Projects

OUR PROJECTS

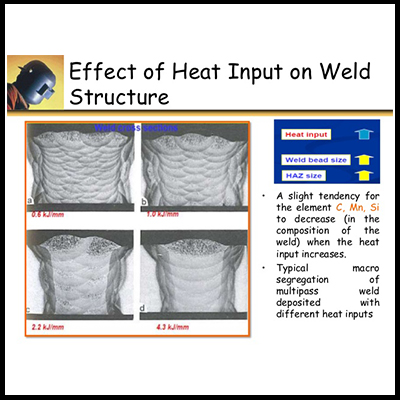

Welding Heat Input

Amount of Heat [Energy in Joules] provided at the Joint for each Pass per unit length of weld in mm [J/mm] as measured by [Arc-Volts x Current x Arc-Efficiency] / [travel-speed]. We offer to provide you ways, means, & measures for complying with International Welding Standards that would control the Heat Input during Welding in your Projects

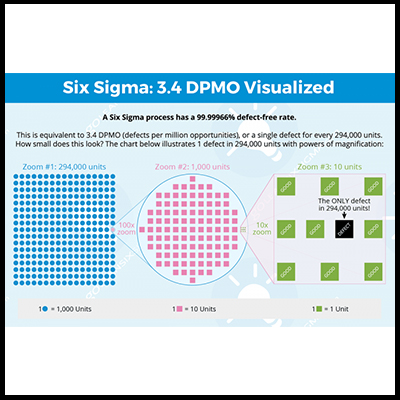

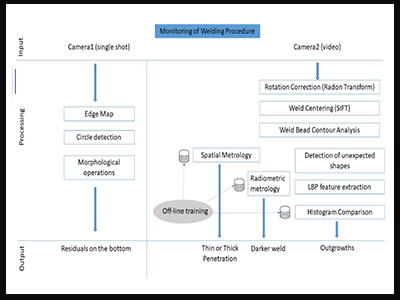

Six-Sigma Weld-Process Control

We offer to provide you ways, means, & measures for complying with International Welding Standards for minimizing the DPMOs to less than 3.4 PPM with the minimum effort & time

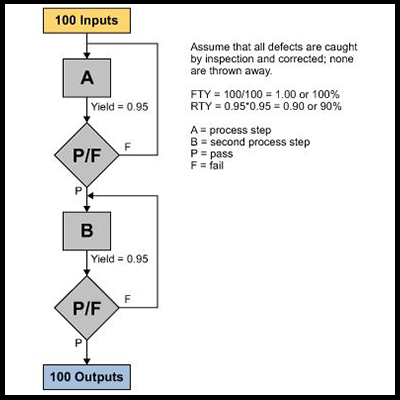

First-Pass Yield [FPY]

We offer to provide you ways, means, & measures for complying with International Welding Standards for achieving FPY with minimum effort & time

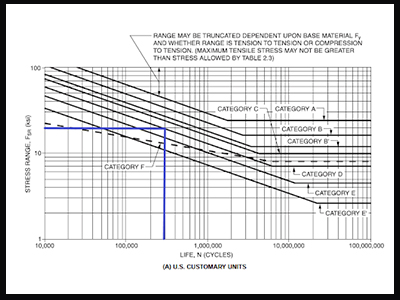

Welding Design

Considers the effect of Joint-Layouts, Material-Weldability Constraints, Stresses & Strains introduced during welding, Welding Procedures, Heat Inputs, Sequence of Bead-Placements, Welding Distortions, Possibilities & Probabilities for the Incidence of Welding Defects, Scope for Detection thru NDT, Performance of the Weldments in Service, Risk-Assessments, Mitigation-Strategy, Reliability Engg, Failure-Prevention, etc. We offer to provide you ways, means, & measures for complying with International Welding Standards for optimizing welding design with minimum effort, time, & expense

Design for Welding Manufacture

We offer to provide you ways, means, & measures for complying with International Welding Standards for optimizing welding production with minimum effort, time, & expense

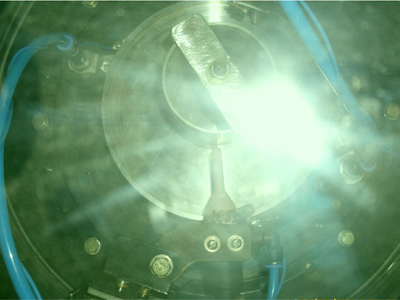

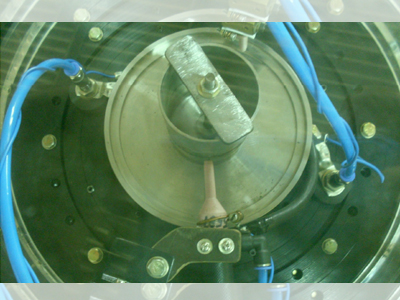

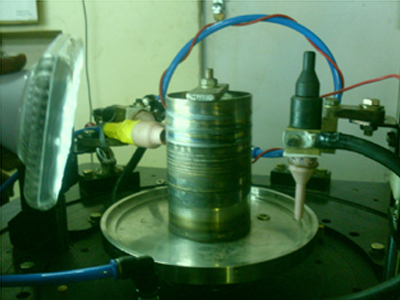

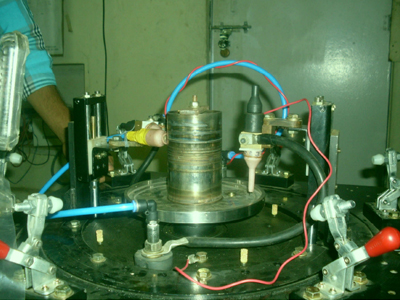

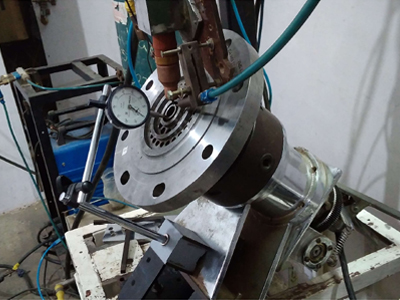

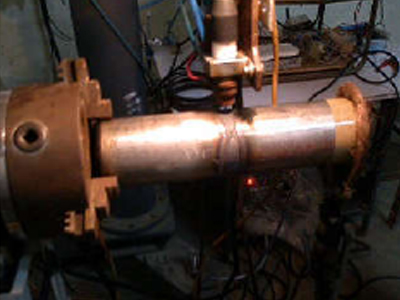

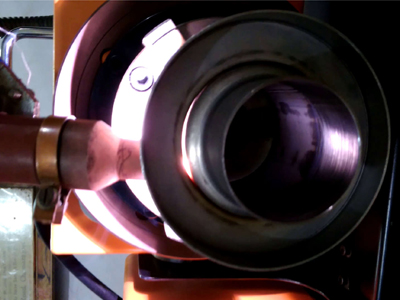

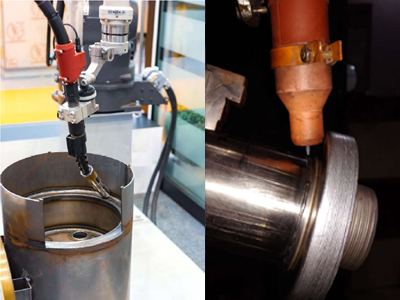

ORBITAL Pipe & Meridian Welding

Techniques for moving the Welding-Tool [Torch, Gun, etc] along the Locus of the Joints of closure Seams in Stationary Work-Pieces like pipe-to-pipe, Shell-to-Shell, Shell-to-Heads, Petals & Cones, etc. We offer to provide you ways, means, & measures for complying with International Welding Standards for optimizing ORBITAL welding with minimum effort, time, & expense

Welding of Prototype Components

We offer to provide you ways, means, & measures for complying with International Welding Standards during welding of limited quantities especially for proving out the feasibility on Prototypes,First-Article Inspections [FAI], Pre-Production Approval-Process [PPAP], etc, for validating processes / proceduresby executing the welding on Mock-Ups&Test-Coupons

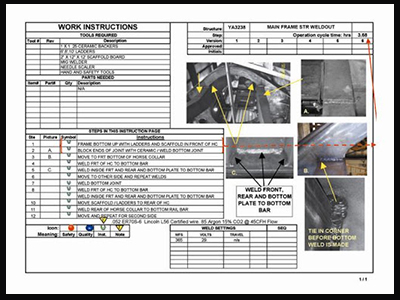

Sequence of Welding & Inspection Plan [SWIP]& Job-Card with Inspection-Report [JCIR]

We offer to provide you ways, means, & measures for complying with International Welding Standards for optimizing the Welding Sequence for specific Joints along with providing their Inspection Plans

Process-Chain Sequence-Map [PCSM]

We offer to provide you ways, means, & measures for complying with International Welding Standards for optimizing the Sequence of Processes in the Chain for specific Jobs / Joints for analyzing their criticalities wrt Welding

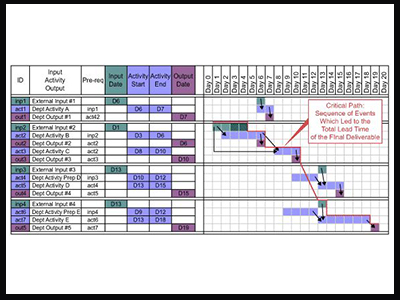

Critical-Path Process-Sheet [CPPS]

We offer to provide you ways, means, & measures for complying with International Welding Standards for optimizing the Processes that make up the critical path in the Project Order

Critical-Component Process-Sheet [CCPS]

We offer to provide you ways, means, & measures for complying with International Welding Standards for optimizing the processes required to weld the critical components

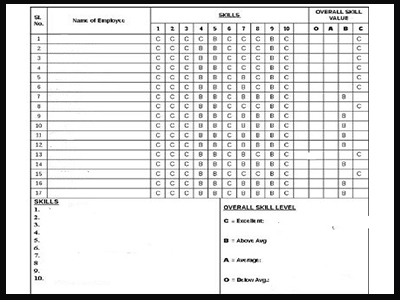

Welder-Competency Map

We offer to provide you ways, means, & measures for complying with International Welding Standards for optimizing the deployment of welding resources thru mapping of the Welders’ Eye-Hand Motor-Coordination [EHMC] Skill-Sets to suit your various Jobs

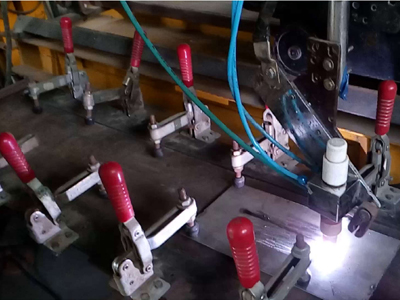

Automatic Welding Cycle

We offer to provide you ways, means, & measures for complying with International Welding Standards for optimizing the Automatic Welding Sequence in the Cycle for welding the required Joint(s)

Robotic Welding System

We offer to provide you ways, means, & measures for complying with International Welding Standards for selecting the right Welding Robots, optimizing their utilization for executing your Jobs

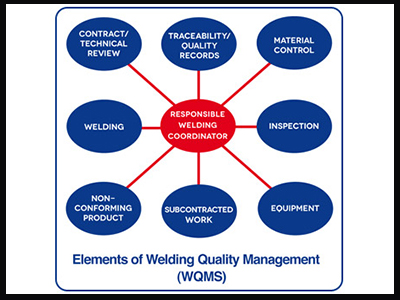

Weld-Management System [WMS]

We offer to provide you ways, means, & measures for complying with International Welding Standards for optimizing the Organization’s Weld

Welding Special-Purpose Machine [SPM]

We offer to provide you ways, means, & measures for complying with International Welding Standards for configuring the right Special-Purpose Machine(s) for automating the welding of your Jobs thru’ designing, developing, manufacturing, supplying, training of your operators, establishing the quality & productivity during pre-production trials

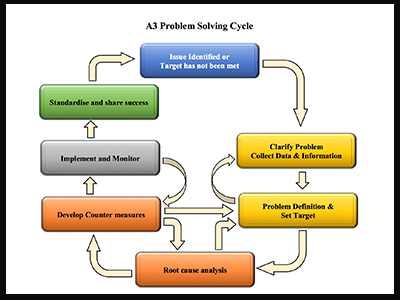

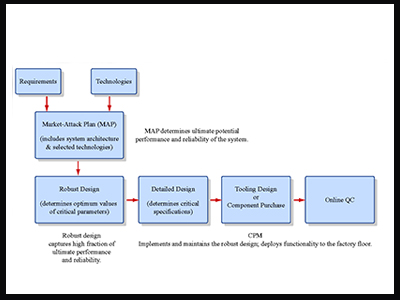

Critical Parameter Management [CPM]

We offer to provide you ways, means, & measures for complying with International Welding Standards for controlling the criticalities through-out the network of activities that obtain the outcomes of our Welding Projects having back-to-back Milestones with your Main-Stream Project

Looking for a quality and affordable for your next project?Contact Us

© 2019 weldsapp • All Rights Reserved