Experience

165 Engg-Years

Promoted by a group of Metallurgical Engrs [PG from IISc & IITs] each with over 4 decades of worldwide experience in Welding-Fabrication & Metal-Processing, endeavour to customize the solution to your Welding, NDT & related Situations… Design for Welding & Manufacture, Failure Investigations, Dissimilar-Metal Combinations, Distortion-Control, Automation, wide range of Processes, Risk-Analysis & Mitigation strategies, Certifications…

FEASIBILITY

We capture your valuable Inputs & propose to customize the Solution to meet your needs to suit the Performance of the Product or Service, provide Prototypes, undertake Design-of-Experiments with different Welding Processes in-house, establish reliability, maintainability, durability, deterioration, failure-modes, etc

METHODOLOGY

We examine the best-in-class Alternatives, createinnovative Options, optimize the Solution, identify Criticalities in the Application / Project, de-Skill the Operations, formulate the sequences of: Fabrication > Assembling > Welding > post-weld operations, In-Process Controls, Jigs & Fixturing,

SATISFIED CLIENTS

We keep on advancing the science,technology,and application of welding that's por mission and it's why we exist.

IMPLEMENTATION

We support you to implement the Solutions, identify the critical Deliverables,work with your Customers & Vendors, re-adapt the Equipment, recommend the Electrodes, Consumables, Fillers, Gas-Mixtures, Train & Certify your Personnel, hand-hold >deploy with Boots-on-the Ground, Remote Monitoring in hostile environments,

Validation

We demonstrate, test & validate the outcomes & performance of our Deliverables both progressively & at Closure.

Request A Solution

De Burden Your Welding

CONTACT USBEST WORK IS OUR PASSION

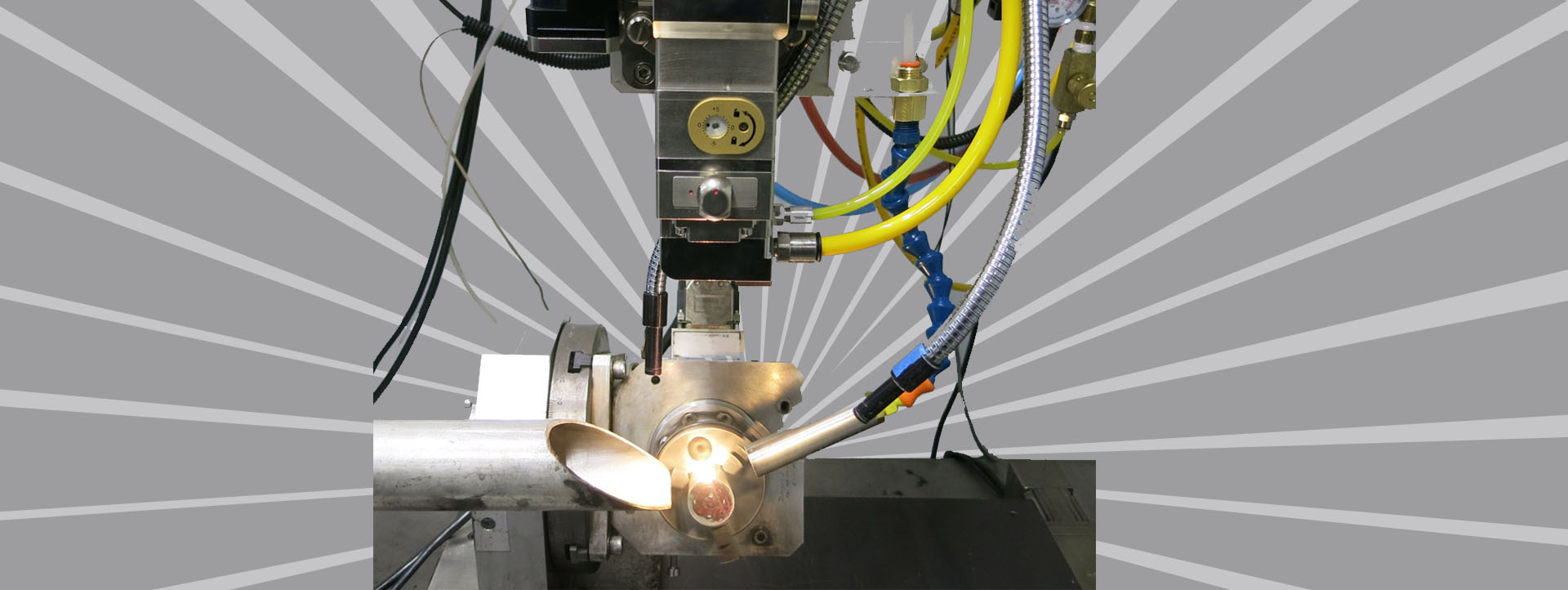

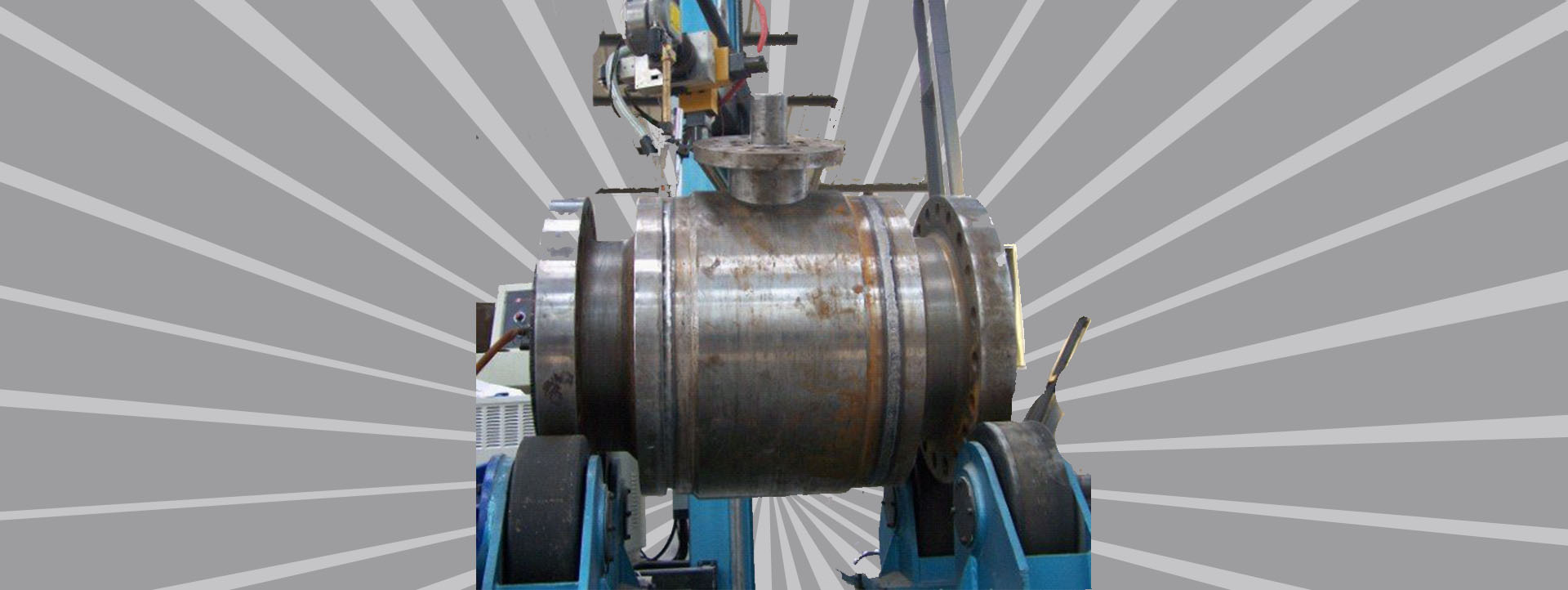

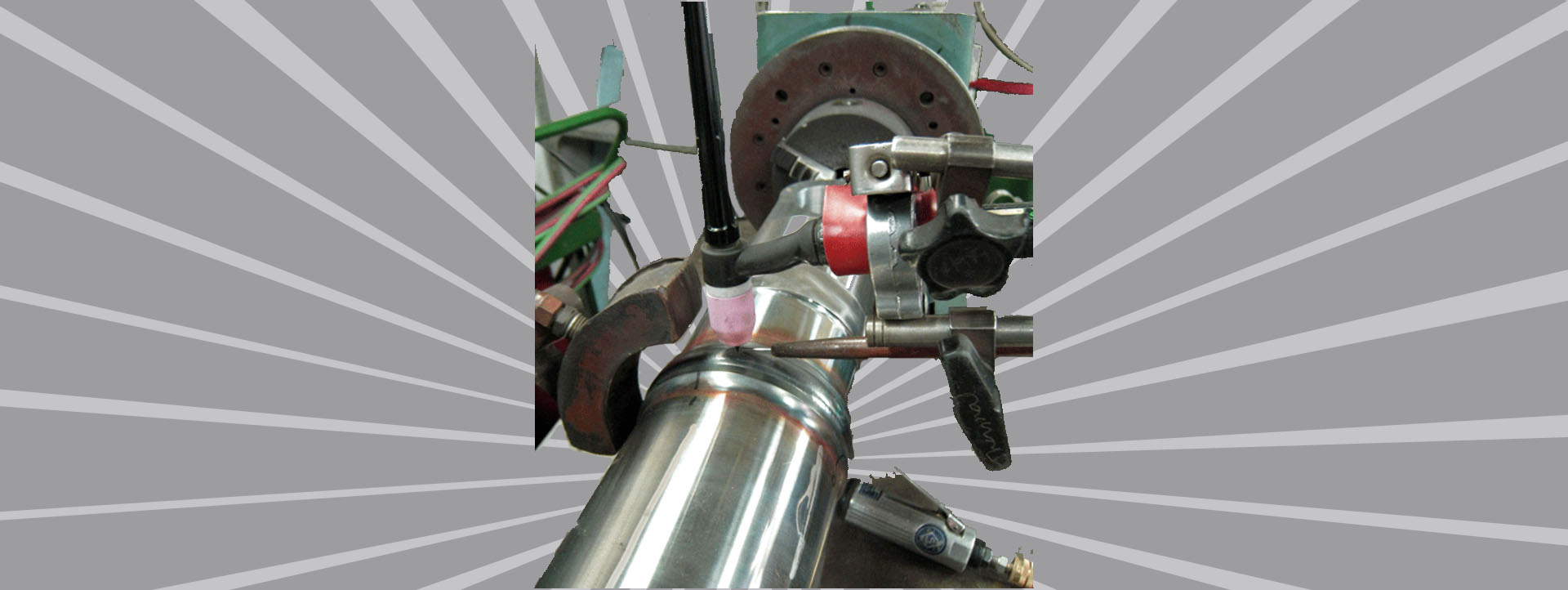

The best solution to your unique welding situations-whether you wish to automate the welding of your components .

Welding Heat Input:

Amount of Heat [Energy in Joules] provided at the Joint for each Pass per unit length of weld in mm [J/mm] as measured by [Arc-Volts x Current x Arc-Efficiency] / [travelspeed].Six-Sigma Weld-Process Control:

We offer to provide you ways, means, & measures for complying with International Welding Standards for minimizing the DPMOs to less than 3.4 PPM with the minimum effort & time.First-Pass Yield [FPY]:

We offer to provide you ways, means, & measures for complying with International Welding Standards for achieving FPY with minimum effort & time.Welding Design:

Considers the effect of Joint-Layouts, Material-Weldability Constraints, Stresses & Strains introduced during welding, Welding Procedures, Heat Inputs.

We are very Happy with the service provided by the Weld Solution App.The quality raw materials used

is

also of good quality.Thank you ..!

Adhirath G

We are very Happy with the service provided by the Weld Solution App.The quality raw materials used

is

also of good quality.Thank you ..!

Anita S T

OUR FEATURED SERVICES

- Welding Process

- Brazing Process

- Soldering Process

- Welding Procedure

- Pre-Production Welding Qualification

- Welder Performance Qualification Certification [WQPC]

- Welding Operator Performance Qualification Certification [WOQPC]

- Weldability of Materials

- Dissimilar Metal Combination

- Welding of Stainless Steels

- Weldability of Non-Ferrous Alloys

- Welding of Aluminum Alloys

- Welding of Nickel Alloys

- Welding of Copper Alloys

- Weldability of Titanium Alloys

- Shielded Metal-Arc Welding [SMAW]

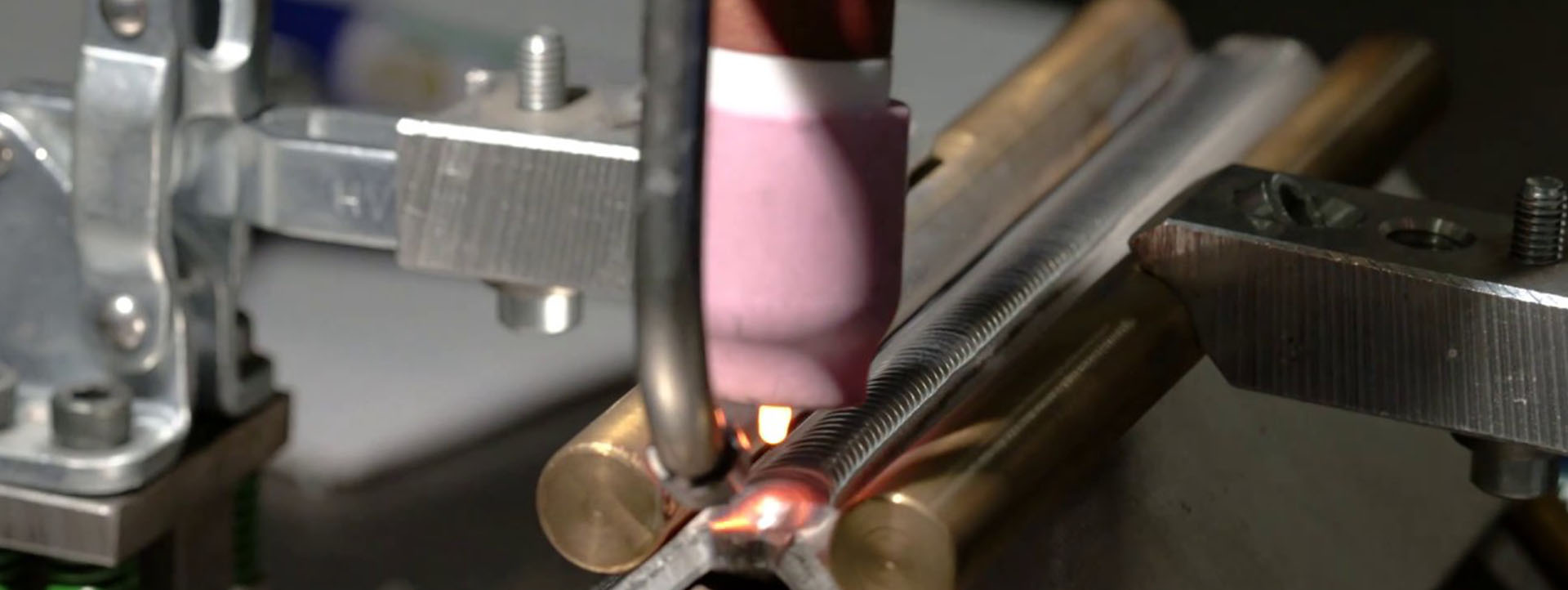

- Tungsten Inert Gas [TIG] Welding

- Metal Inert Gas [MIG] Welding

- Flux-Cored Arc Welding [FCAW]

- Metal-Cored Arc Welding

- Submerged-Arc Welding [SAW]

- Electro-Slag Welding [ESW]

- Resistance Welding

- Friction Welding Process

- Friction-Stir Welding Process

- Welding Procedure Qualification Record

- Remote Weld-Management System [WMS]

- Welding Distortion

- Weld-Joint Layout

- Weld Map

- Positional Welding

- Complete Joint Penetration [CJP] in Welding

- Welding Defects

- Weld-Failure Analysis

- Recommended Welding Parameters

- Weld Data Record [WDR]

- Weld Data Card [WDC]

- Welding Cracks

- Weld Heat-Affected Zone [HAZ]

- Radiographic Testing [RT] of Welds

- Ultrasonic Testing of Welds

- Leak Testing of Weldments

- Welding Performance Validation

- Welding Symbols

Looking for a quality and affordable for your next project?Contact Us

© 2019 weldsapp • All Rights Reserved